Estonian Cell is no chemical cellulose mill, it needs to be explained – all it produces is mechanically crushed pulp.

«As the Kehra plant, for instance, uses conifers as raw material with chemical boiling applied, we are mechanically making pulp which makes production very energy-intensive,» explained Ms Lahe.

The only chemical treatment happening is bleaching with hydrogen peroxide. These are the same chemical and process as ladies (and gentlemen) use to bleach their hair.

Depending on what kind of paper is desired, various celluloses and pulps and other stuff are combined. Aspen has short fibre and is therefore unfit for strong paper. Therefore, Kunda’s produce is not used in Kehra as they make kraft (sack) paper.

The larger part of pulp produced in Kunda goes into making printing paper, followed by cardboard and a smaller selection of soft and special papers.

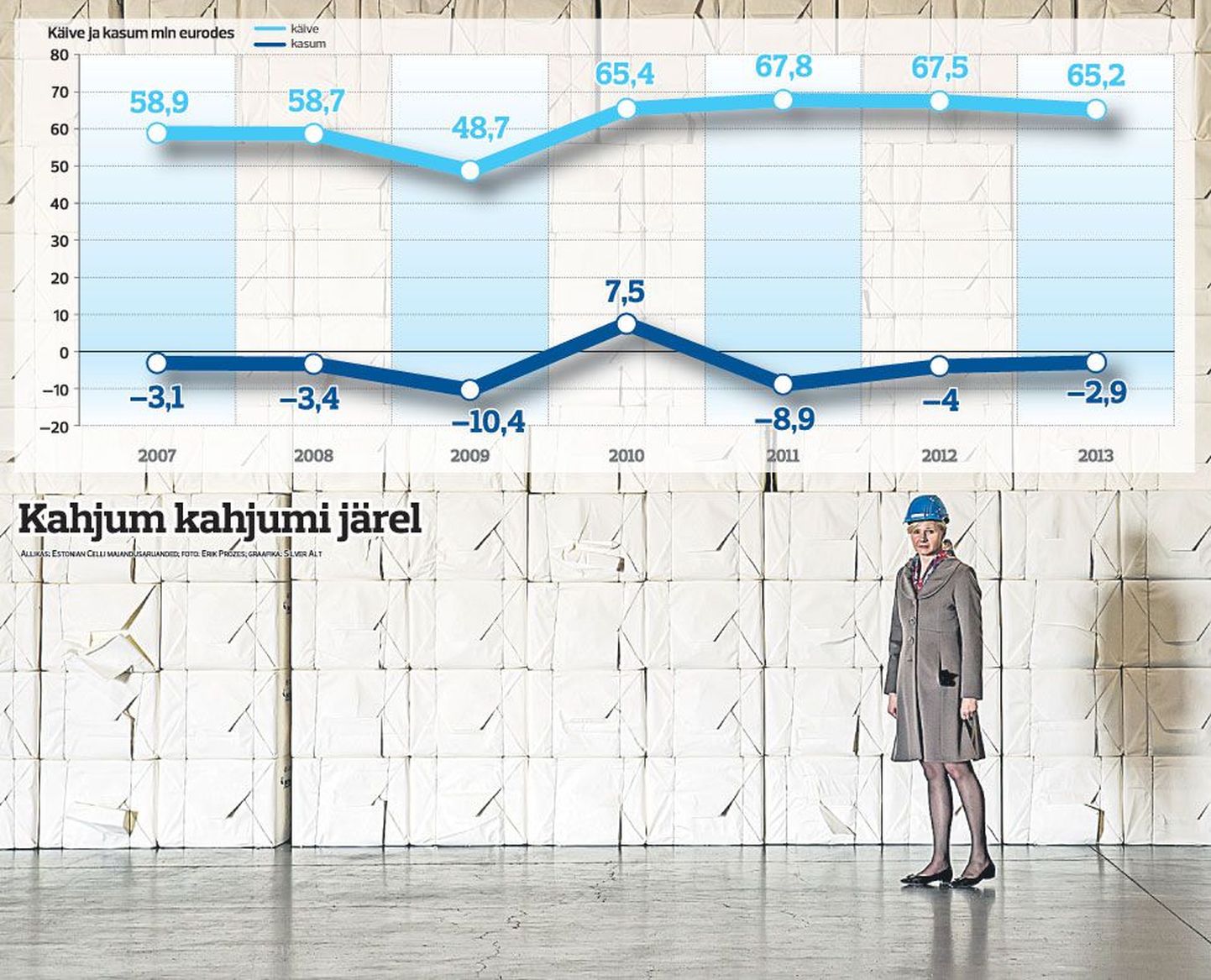

Beholding the sad financial state of the company, one is prompted to ask: did Estonia actually need the large investment into the resource-intensive industry? Economy ministry insists the Estonian Cell investment was very important for Estonia, and the ministry considers it important for the company to continue in Estonia. Still today, the state is striving towards such foreign investments which boost productivity and create jobs with greater added value.

Estonian Cell employs 85 people; however, when also considering collecting of wood, logistics, and the entire production chain, about 500 people are employed by the company. Labour productivity per employee is among the highest in Estonian industry: net sales turnover is €709,000 a year per person.

Were aspen wood sold as logs, export turnover would amount to €13m; thanks to the plant, added value is increased five times. «13 million becomes 67 million euros,» said Ms Lahe.